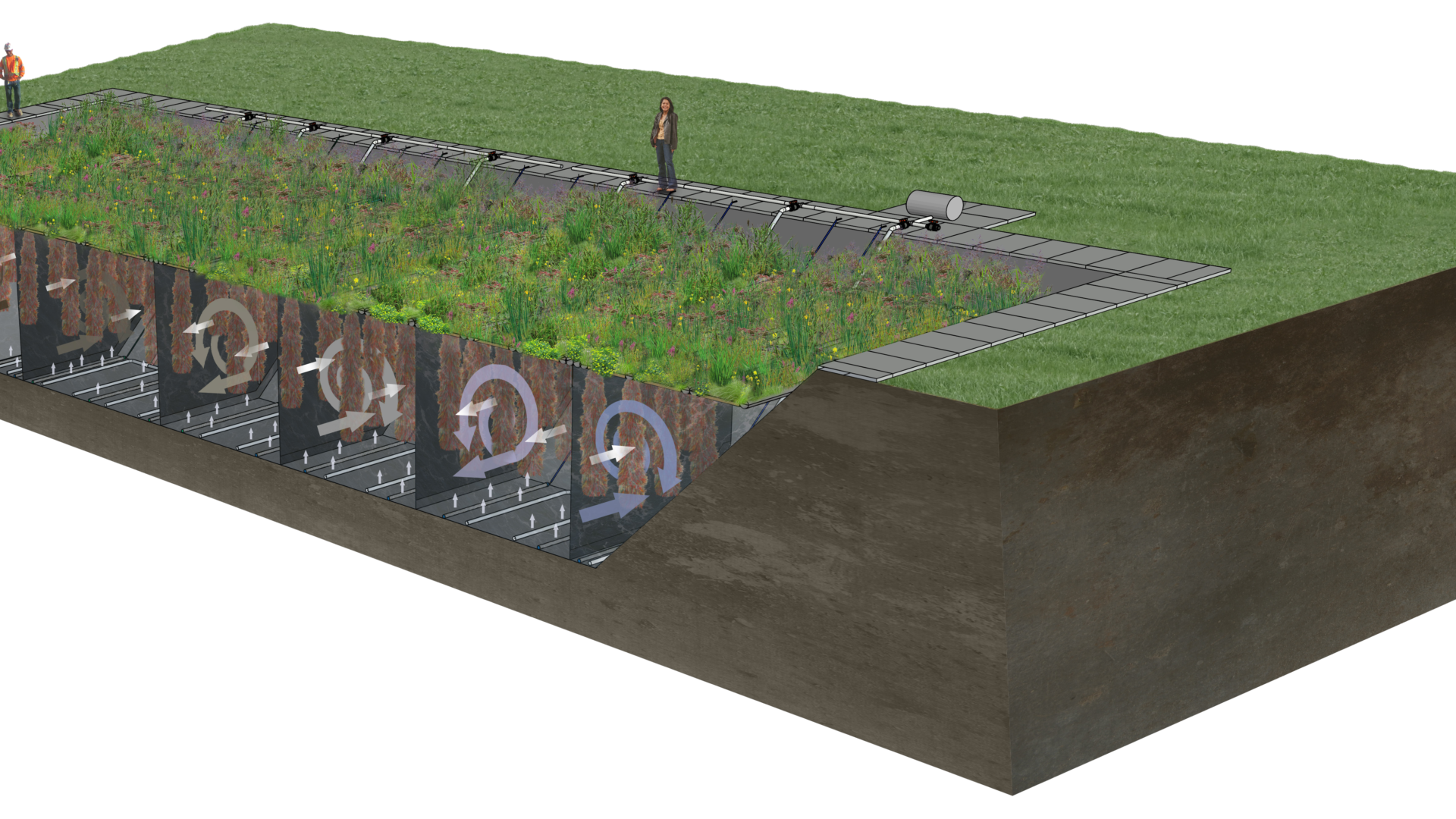

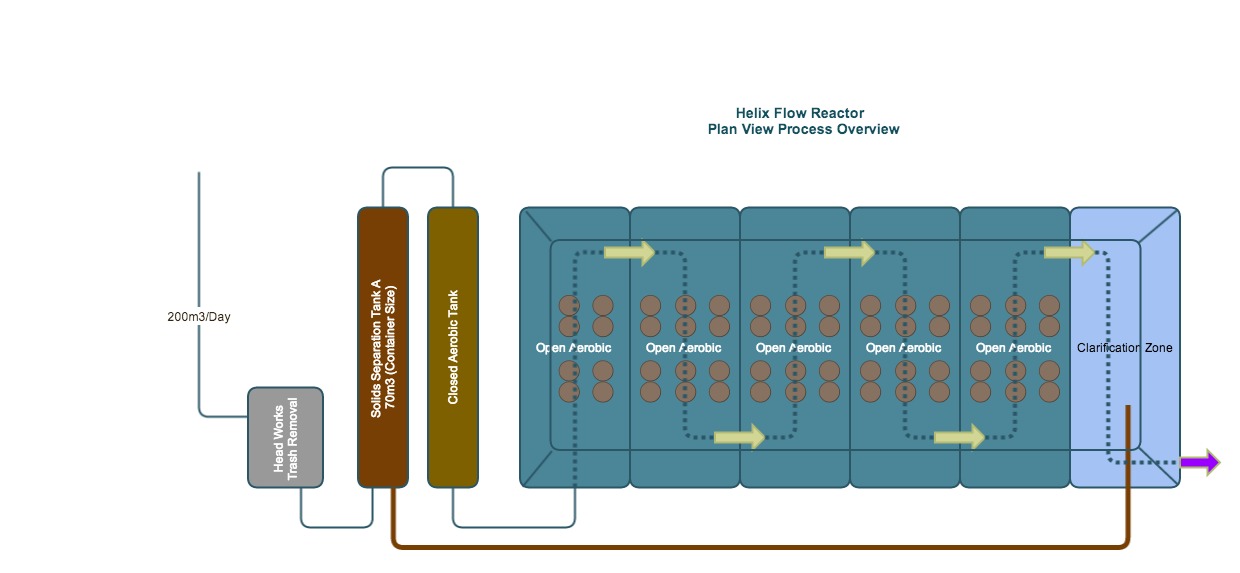

Powerful Flexible Treatment

The Helix Flow Reactor integrates the latest developments in ecological engineering with traditional wastewater treatment processes to offer a more flexible, powerful and long lasting version of the tried and tested reed bed technology. It is less than a tenth of the size per person equivalent and can handle higher BOD and COD influent. It can be used on its own or as a primary treatment stage before a smaller constructed wetland system.